Thus, we give more efficient and cost-effective solutions to manufacture processes that involve complex needs. To joint these components two types of laser welding can be used, depending on the angle and the pieces position, and these are overlap seam and Butt joint.

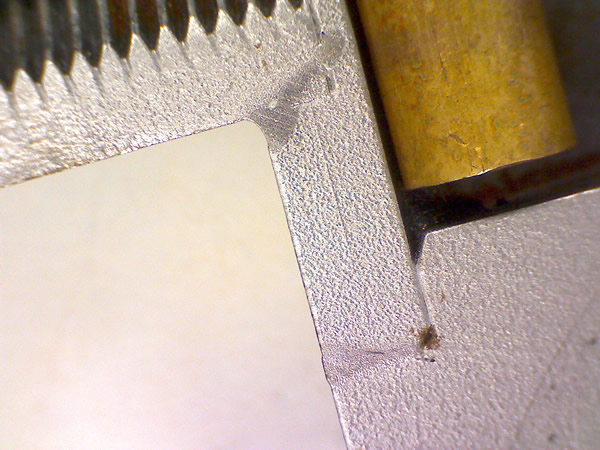

Butt joint welding is used in accessible welding areas, and is the welding depth penetration which determines the resistance.

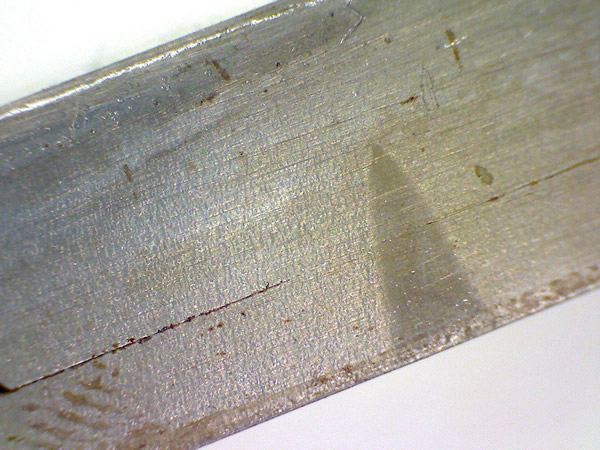

Instead, Overlap welding is used to pass through materials, welding pieces in areas that are not accessible to other technologies. For this type of welding, is the heating cone section produced in the parts in contact that determinates the welding resistance.

Two circular pieces that are butt joint.

Detail with three welding focus. The first welding (above) performs a butt joint welding on the outside of the piece and a overlap welding on the inside. The second butt seam welding (below) joints the pieces welded before together with a third piece.

Overlap welding between two longitudinal pieces.